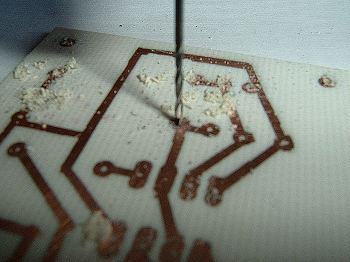

Drilling the PCB

|

The leads on components come in a variety of diameters but, for normal use, I've found a drill bit of

0.75mm diameter seems best. However, if you need to buy some drill bits, it would be worth getting

0.5mm, 0.75mm, 1mm and 1.5mm sizes. One or two around 3mm are useful for drilling holes in the corners of

the PCB for mounting in a case. Fibreglass PCB is very hard on drill bits so, if you think you'll be making more projects, it's worth buying several of each because they're virtually impossible to sharpen at home. |

I've had my model-maker's drilling machine for over 30 years now and it's still going strong! It's a small hand-held 12 volt drill that needs a reasonably steady hand with the tiny drill bits. Don't press too hard (just the weight of the small drilling machine is enough) or the bit will break. Take your time drilling the holes and, when you think you've finished, check for any holes you've missed! Almost certainly, you will miss one or two first time round!

|

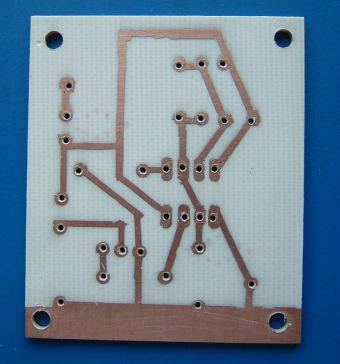

And here it is at last! Give the copper tracks a final clean and the board is ready for the components. |